I get quite some questions regarding the water household in the new paludarium. When I try to explain, I was always like “wish I had a picture of this”. And now I do!

Introducing “The WaterWorx”

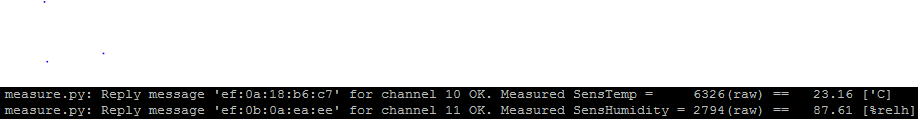

The WaterWorx is a compilation of all water management related things that drive the paludarium. It consists of pumps, valves, tubes, containers, level sensors and things like a reverse-osmosis unit. All of these things are controlled by Artemis, the embedded controller (that is actually Arduino based). The Raspberry Pi on top of Artemis also does some monitoring and higher-level controlling as well. To just drop you an image of the WaterWorx, here it is:

RSS

RSS LinkedIn

LinkedIn Twitter

Twitter Email

Email

[…] to the “C”. Today I still program in both “C” and Python for fun (Arduino and Raspberry Pi […]